OptiGalv is the intelligent solution for your electro-plating line (electro-galvanic plant).

From small plants with 10 containers and 1 crane to huge plants with 200 or more containers and with 8 or more cranes.

It is easy to use Optigalv, as everything can be configured in a very user friendly way to meet your needs, which makes Optigalv accessible for everybody.

It would be too extensive to show solutions for every type of plant. The following shows a solution with 63 containers and 3 cranes.

Forget all about making those difficult time and routing diagrams that is nothing but trouble on your sequece-controlled plant.

With Optigalv you are not limited by a simple sequence. You just have to make a recipe that follows your desired route through the plant, with the times and currents that is appropriate for the selected product. You do not even have to think about which crane has to do the transport. OptiGalv controls this. Plain and simple.

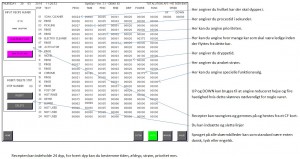

(Click to view full size picture)

In the recipe you can easily choose which containers you want to use, how long time, which current, time for drip, priority etc. OptiGalv can handle different recipes at the same time, and the cranes divide the work between themselves automatically. With OptiGalv all you have to think about is the chemistry and the production, and if you want to introduce new chemistry to the plant, or make another route through the plant, you just have to make a new recipe to apply the changes.

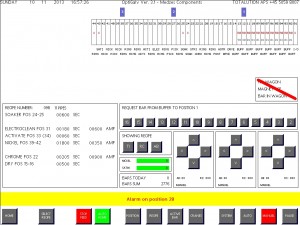

On the main screen you have a complete picture of the plant, cranes, recipes, bars etc.

(Click to view full size picture)

For instance, you can make the screen shift between showing the remaining time in a container, the recipe in container, or the active bar in the container.

By having a buffer between the plant and the load position, you are able to be ahead or behind the plant timewise, without getting a halt in the production. OptiGalv will automatically bring the goods you have prepared and placed in the buffer every time there is room in the plant. Furthermore it will bring the finished goods to you, and if you are not ready to receive it, it will deliver them to the buffer.

Even more so, you can let OptiGalv start automatically before you get to work in the morning, if you have placed goods ready in the buffer the day before. The plant will then be up and running by it selve before you are done with your morning coffee.

Optigalv is intelligent management of surface treatment on one hand, and healthy economy on the other.

Call +45 50598007 if you would like a demonstration to get a hands on experience with OptiGalv

For more information in danish go to www.optigalv.dk

For more information in English … presse here